Customer Services

Copyright © 2025 Desertcart Holdings Limited

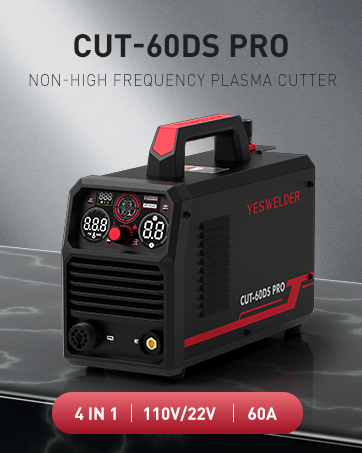

⚡ Cut smarter, not harder—power meets precision in every spark!

The YESWELDER CUT-60DS PRO is a professional-grade 60Amp plasma cutter featuring a non-high frequency blowback start system for smooth, interference-free operation. Equipped with a digital display for real-time monitoring and a non-touch pilot arc torch, it delivers precise, clean cuts on rough or painted metals. Dual voltage compatibility (110/220V) and advanced safety protections make it a versatile, reliable tool for automotive, metalwork, and DIY projects.

| ASIN | B09L3Y3ZLF |

| Batteries Included? | No |

| Batteries Required? | No |

| Best Sellers Rank | #13,656 in Automotive ( See Top 100 in Automotive ) #9 in Plasma Cutting Equipment |

| Color | Black, Red |

| Customer Reviews | 4.3 4.3 out of 5 stars (803) |

| Date First Available | November 5, 2021 |

| Display Style | digital |

| Item Package Quantity | 1 |

| Item Weight | 21.4 pounds |

| Item model number | CUT-60DS PRO-1 |

| Manufacturer | YESWELDER |

| Material | Metal |

| Number Of Pieces | 1 |

| Part Number | CUT-65DS |

| Power Source | Power Supply |

| Product Dimensions | 15.75 x 5.91 x 11.81 inches |

| Style | CUT-60DS PRO-1 |

| Warranty Description | 1 year |

| Wattage | 50 milliamp_hours |

S**E

Works awesome , great value

Works great so far , only used to cut 1/4 plate as of now but looks to be very good quality/easy to use, and should last a long time . Can’t beat the price

J**Y

Great tool great price point

Glad I waited, but also wish I had bought one sooner. Thing works like a champ. Cuts through 1/4" mild with scale in a hurry. Saving me a ton of time on prep.

T**R

I guess it's the operator that makes the difference . Good quality .

This one works like the rest . Does a good job at cutting 1/2" easying

R**S

This little guy is a monster for the price.

The first picture is a cut in 3/16" plate after I installed it on my crossfire plasma table. I'm still playing with the setting to get it dialed in. The minor issues im having are more related to the crossfire system and not the plasma cutter itself. The second picture was just playing the plasma cutter straight out of the box at 65A and 80psi. It cuts through 1/2" like nothing. I'm impressed, especially for the fact that you can get this machine for less then $300.00. My other plasma cutter is a hypertherm 30xp that payed almost 2k for and this is comparable in performance. This is not designed to run on a cnc table however is not hard to get out to work. Im playing with the setting on the whole machine in general to see what it's capable of but for the price it is tough to beat. The short time I played with the plasma cutter itself it never failed to strike an arc but for some reason it fails to strike an arc on a rare occasion when installed on the cnc table. Again, that's an issue with the machine and Not the cutter. If your in the market for a plasma cutter, don't hesitate on this little guy. It packs a punch for such a compact unit. It's impressive!!

G**E

Very nice plasma cutter that I definitely recommend.

I am an old guy that started welding and fabricating right at 40 years ago. I have never used a plasma cutter nor have I ever seen one used. I have often seen the results of plasma cutting when contractors would arrive with certain pieces of steel and was always amazed at how smooth the cuts were. I have always used and preferred oxygen and acetylene. I never liked oxygen and propane unless I was cutting out very thick stainless where precision was not needed. A couple of weeks ago I decided that I needed a plasma cutter for a gate project that I am about to start. The metal is not real thick so precision cuts are priceless for a satisfactory outcome. I bought a YesWelder auto darkening hood a few years ago and it has performed awesomely so I decided to try this plasma cutter. I finally got an opportunity tto try it out this morning on some scrap pieces of 14 gauge structural steel. Upon initial power up, I noticed that the controls are very straight forward and easy to use. The amperage and the PSI are easily adjustable. This thing worked amazing. I had it connected to 220V supply power. I set it at 35 PSI and 30 Amps. It easily cut through the metal as I expected it to do but to my surprise, there was no slag byproduct on my floor, it is very easy to use, I can use it with nothing more than a good pair of dark safety glasses, and I consumed not 1 Psi of oxygen or acetylene. I should have purchased one of these 20 years ago. Now they are affordable enough for the home fabricator. This is my new go to for my metal cutting needs. In my opinion this is a game changer. YesWelder is a very well made product and I am confident that this unit will last me a very long time. I recommend this product to anyone that has been thinking about one but has not yet pulled the trigger. I think I got a lot of value for my money. I hope this helps.

J**R

CUT-65DS Promising Features Marred by Inconsistent Performance

At first glance, this plasma cutter seemed to have all the features I was looking for. The digital displays were impressively bright and crystal clear, providing easy visibility of settings. Adjustments were intuitive and user-friendly, allowing for quick and convenient setup. The torch handle felt sturdy and of high quality, providing a comfortable and secure grip. However, my excitement quickly turned to disappointment when I began using the machine. Despite meticulously following the instructions, connecting everything correctly, and ensuring the power switch was turned on, the plasma cutter's performance was far from reliable. When I pulled the trigger, I anticipated a powerful plasma flame, but to my frustration, only a rush of air emerged from the nozzle. This lackluster result occurred repeatedly, with the plasma flame appearing a mere three out of ten times. The inconsistency in performance was deeply unsatisfying and raised doubts about the machine's overall reliability. It is disheartening to encounter such issues, especially when the machine showcased promising features. The bright displays and user-friendly adjustments, coupled with the high-quality torch handle, were overshadowed by the machine's inability to function consistently. Regrettably, I had to reach out to customer service in hopes of resolving the issue. They said it was a fluke and suggested getting a replacement. However, their proposed solution did not rectify the problem. Additionally, I noticed a substantial air leak inside the case of the second plasma cutter, further underscoring the quality control issues. Ultimately, I had no choice but to return both plasma cutters. Unfortunately, this experience not only wasted precious time but also caused significant delays in my project. It is evident that these repeated issues are not mere flukes but rather indicative of a larger quality control problem. In conclusion, while the bright displays, intuitive adjustments, and high-quality torch handle initially seemed promising, they were marred by the plasma cutter's inconsistent performance. I would caution potential buyers against considering this particular model, as the unreliability and quality control issues detract from its otherwise appealing features. Look for a more dependable option from a reputable brand to avoid such frustrations and setbacks.

S**.

Detalle que se encontraron el switch de encendido se sale de su alojamiento se contamina pronto la boquilla de corte con la guía y se quema la boquilla protectora se hacen pruebas sin la guía funciona mejor no se contamina pronto la boquilla de corte no se quema la boquilla protectora cortando el material y antorcha a una distancia correcta hay que tener buen pulso para llevar la antorcha en una separación correcta se cortan placa de acero en 5/16 máximo 3/8 utilizando el equipo en 4T hay que tener una alimentación de aire constante calibrando manometro funciona bien el equipo esperemos que de batalla en el trabajo

A**X

I was excited to put my new plasma cutter to work but I ended up having to fix it first! When I first powered it on the fan came on right away but the display did not after a few minutes of troubleshooting I decided to open the case and have a look and sure enough the main conector going to the display was unplugged,once plugged back in all works fine. There is no selastic on any of the conectors and quite a few of the conectors used have a very insecure locking design. That sed this plasma cutter out cuts my previous one 10/1 truly a beast ! I cut several linear feet of 5/8 plate and looking at the consumables you can hardly see any degradation at all and it cut that plate like butter. PLEASE ADD SELASTIC TO ALL CONECTORS!

M**E

Great cutting tool

G**Y

Trustpilot

2 months ago

4 days ago