Kundendienst

Copyright © 2025 Desertcart Holdings Limited

🖌️ Transform your 3D prints from prototype to perfection—no sanding required!

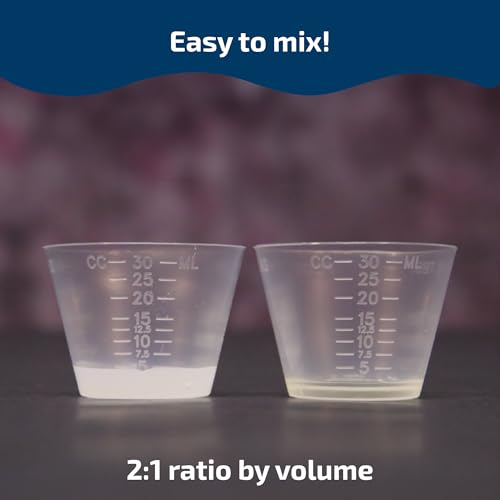

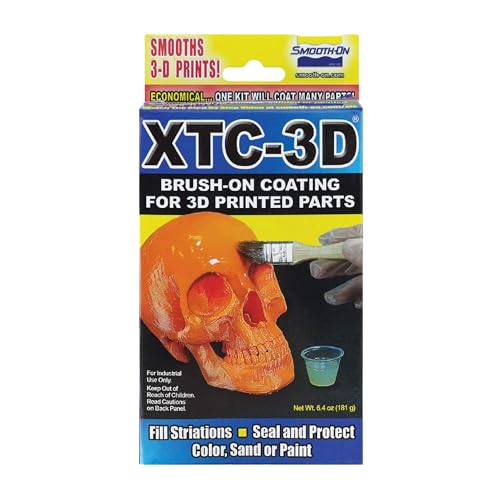

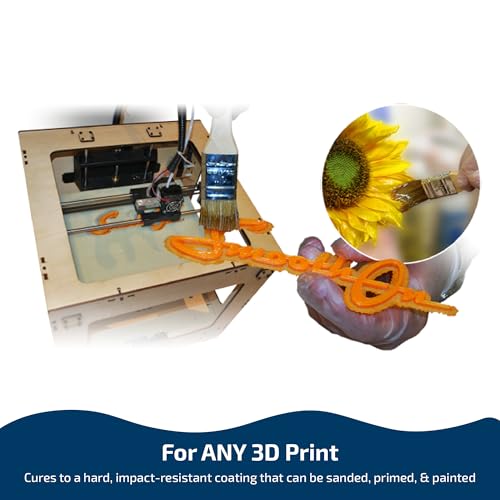

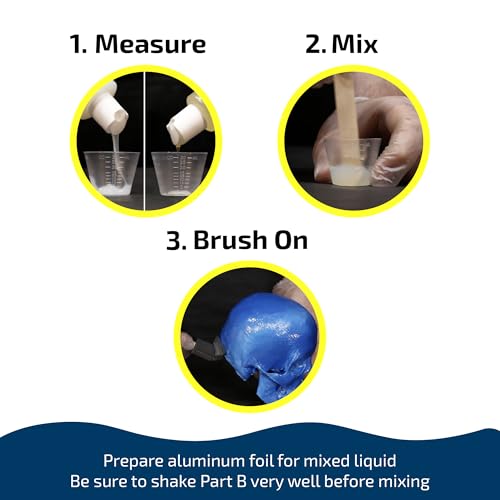

Smooth-On XTC-3D is a high-performance epoxy coating designed specifically for 3D printed objects. With a simple 2:1 mix ratio, it self-levels to smooth out layer lines and create a durable, impact-resistant finish compatible with FDM, SLA, and SLS prints. One ounce covers 100 square inches, making it an efficient solution for hobbyists and professionals alike. Heat-resistant up to 150°F and moisture-proof, it’s sandable and paintable after curing, enabling flawless, customizable results without the hassle of traditional sanding.

| ASIN | B01BKSLI9M |

| Item model number | xtc3d |

| Manufacturer | Smooth-On, Inc. |

| Product Dimensions | 5.08 x 8.89 x 17.27 cm; 290 g |

J**E

XTC-3D is hands-down a must have for anyone with a 3d printer. I usually print in ABS and follow the old "tried and true" method of sanding followed by vapor smoothing followed by final sanding before painting. XTC-3D eliminates the need for all that extra effort. To ensure a problem-free flawless finish: - Make sure that your part is clean. Use isopropyl alcohol, acetone, or whatever appropriate cleaner for your material to wipe your print clean - Mix the resin with the hardener in the exact ratio specified. Adding more hardener than necessary will only increase difficulty in applying it. Make sure that you mix it THOROUGHLY! I cannot stress this enough; You must mix it and continue mixing it until it becomes crystal clear. The longer you mix it, the better your finish will be, but the shorter your working time will be. I recommend mixing small batches at a time - you can always mix more if you run out. - Make sure that the ambient temperature is within the recommended range. Trying to coat your print when the temperature is below 70F will obviously increase the time it takes to fully cure. The mixing cup that is included is flimsy and not very strong. I made the mistake of mixing a batch and leaving it in the cup while applying it and the heat nearly turned the mixing cup into jellly and rendered it worthless. After mixing, pour it into another container, onto some aluminum foil, etc then wipe the mixing cup out with a shop towel, paper towel, etc. The foam brush is not worth the hassle - this holds true for ANY foam brush. I recommend you get a decent paintbrush instead. The foam brush soaks up too much and deteriorates too quickly, but a paint brush can be cleaned out with acetone and reused several times. I was so impressed with this stuff that I ordered 24oz of it. Follow the directions, do the prep work and you will end up with repeatable flawless results.

S**N

Great stuff if you’re doing 3-D prints

P**E

As advertised as a solution to smoothing out 3D prints, the XTC Coating works very well. It seems to be essentially a resin that is mixed in two parts and applied to your model with a disposable rubber brush. It works very well but the biggest problem is that the resin settles in the deepest areas (which of course it's meant to do) and generally smooths out any fine detail. I was able to smooth out two models using very little product and the results were favorable though any coating will still require additional sanding to really make the finished product look perfectly smooth. Caution is required because like any resin, it requires working in a well ventilated area and you should probably use rubber gloves to stop contact with skin. For the price, it's not a perfect solution but it is a great product and does what it advertises.

H**D

I had imagined such a product since I began printing in 3D with an FDM machine and I'm glad I discovered XTC-3D High Performance 3D Print Coating. One drawback to FDM printing is that prints are not fluid tight. While I won't say this coating will make prints completely water tight under pressure, It goes a ling way to eliminating the small pores left in the print by the FDM process. Now my prints for fountain heads and water features, if coated inside and out, work very well without any pinhole leaks. The trick is making the inside large enough so the applicator will fit. The kit comes with only one mixing cup and one sponge applicator so plan on a trip to the craft store for more, because there is enough of the part A and B material for many applications. The result is a hard clear surface that you can sand or paint if you so desire.

M**S

I bought this to smooth 3d printed miniatures and it works great. It does eliminate some fine details, but also smooths layer lines and gaps wonderfully. The mixing is simple to eyeball for the tiny amounts used on miniatures and the 10 minute work time is not a hindrance - just don't try to do more than a few minis per batch or it will solidify on you.

TrustPilot

vor 2 Monaten

vor 1 Monat